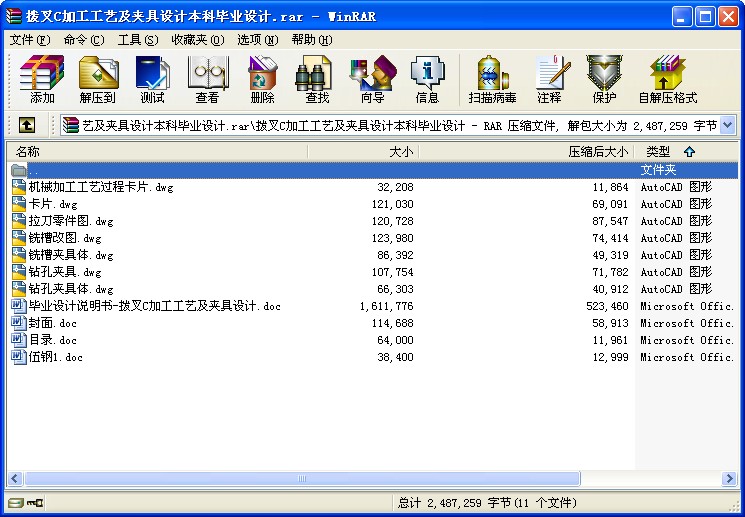

撥叉C加工工藝及夾具設(shè)計本科畢業(yè)設(shè)計

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 撥叉C加工工藝及夾具設(shè)計本科畢業(yè)設(shè)計

摘 要

此次設(shè)計任務(wù)是對撥叉C零件的加工工藝、夾具以及拉刀設(shè)計,該工件由于上端面和底槽均與花鍵孔中心有位置關(guān)系,因此在工序安排上,先加工花鍵孔,再通過花鍵孔定位加工底槽和上端面,最后攻螺紋孔,其中各種夾具均采用專用夾具,由于該零件的尺寸小,所需的夾緊力不大,因此都采用手動夾緊,它的機構(gòu)設(shè)計簡單、方便,且滿足夾緊要求。在設(shè)計拉刀時,根據(jù)零件材料、切削余量等,選擇并計算拉刀的各種參數(shù),如拉刀的容屑槽、拉刀齒升量、拉刀齒型及齒數(shù)等并根據(jù)這些參數(shù)畫出拉刀工作圖。

關(guān)鍵詞 撥叉C,加工工藝,定位,夾緊,拉刀

ABSTRACT

This design is to analyze the processing of plectrum C,tongs designs,and pulling knife designs,Because during the machining process,the top end and bottom slot of the workpiece are related to the core position of the key bore.then passes to spend key bore fixed position process the bottom slot with top end,offend the chread bore finally.And every kind of tongs adopt the appropriation tongs.Because such workpiece is small in its size and calls for a little clip tight,therefore all tongs adopt moving to clip tight.Its arganization design is simple,convenience,and satifly to clip tight,when designing the broaching cutting tool,this design choses and computes every kind of parameters,such as,the material of the broaching cutting tool,the rising level of the broaching cutting tool,the type of the pulling knife gear,and the number of the gears and so on,through the material of spare parts and cutting remaining measures,

Key words Plectrum C, the processing craft, position, clip tight, broaching cutting tool.

目 錄

摘要…………………………....………………….……………………...Ⅰ

ABSTRACT.....................................................................................................Ⅱ

1 緒論..........................................................................................................3

2 撥叉C的分析.............................................................................................4

2.1撥叉C的作用...........................................................................................4

2.2撥叉C的工藝分析.....................................................................................4

2.3撥叉C的工藝要求.....................................................................................4

2.4毛坯的選擇..............................................................................................5

2.5 本章總結(jié)................................................................................................5

3 工藝規(guī)程設(shè)計.............................................................................................6

3.1加工工藝過程...........................................................................................6

3.2確定各表面加工方案..................................................................................6

3.2.1選擇加工方法時,需考慮的因素.............................................................6

3.2.2面的加工...........................................................................................6

3.2.3孔的加工...........................................................................................7

3.2.4槽的加工...........................................................................................7

3.3確定定位基準...........................................................................................7

3.3.1粗基準的選擇.....................................................................................7

3.3.2精基準選擇的原則...............................................................................8

3.4工藝路線的擬訂........................................................................................8

3.4.1工序的合理組合..................................................................................8

3.4.2工序的集中與分散...............................................................................9

3.4.3加工階段的劃分................................................................................10

3.4.4加工工藝路線方案的比較....................................................................11

3.5撥叉C的偏差,加工余量,工序尺寸及毛坯尺寸的確定.......................................12

3.5.1毛坯的結(jié)構(gòu)工藝要求..........................................................................12

3.5.2撥叉C的偏差計算.............................................................................13

3.6確定切削用量及基本工時(機動時間)..........................................................14

3.7時間定額計算及生產(chǎn)安排..........................................................................22

3.7.1鉆預(yù)制孔.........................................................................................22

3.7.2鉆預(yù)制孔.........................................................................................23

3.7.3拉 25H7內(nèi)花鍵................................................................................23

3.7.4粗、精銑18H11底槽........................................................................................23

3.7.5粗、精銑上端面...............................................................................................24

3.7.6鉆、攻2-M8螺紋孔.........................................................................................25

3.8 本章總結(jié)..............................................................................................................26

4 專用夾具設(shè)計..........................................................................................................27

4.1銑槽夾具設(shè)計........................................................................................................27

4.1.1研究原始質(zhì)料.................................................................................................27

4.1.2定位基準的選擇..............................................................................................27

4.1.3夾具方案的設(shè)計選擇.......................................................................................27

4.1.4切削力及夾緊分析計算...................................................................................27

4.1.5誤差分析與計算..............................................................................................29

4.1.6夾具設(shè)計及操作的簡要說明............................................................................29

4.2鉆、攻2—M8螺紋孔夾具設(shè)計..................................................................................30

4.2.1研究原始質(zhì)料.................................................................................................30

4.2.2定位基準的選擇..............................................................................................30

4.2.3夾具方案的設(shè)計選擇.......................................................................................30

4.2.4切削力及夾緊力的計算...................................................................................30

4.2.5誤差分析與計算..............................................................................................31

4.2.6夾具設(shè)計及操作的簡要說明............................................................................32

4.3 本章總結(jié)..............................................................................................................32

5 花鍵孔 25H7拉刀設(shè)計..........................................................................................33

5.1拉刀的結(jié)構(gòu)參數(shù)....................................................................................................33

5.1.1拉削特點........................................................................................................33

5.1.2拉刀類型選擇.................................................................................................33

5.1.3拉刀材料選擇.................................................................................................33

5.1.4拉床類型選擇.................................................................................................33

5.2拉刀切削部分的設(shè)計.............................................................................................33

5.2.1拉削方式選擇.................................................................................................33

5.2.2齒型確定........................................................................................................33

5.2.3拉削余量的確定.............................................................................................34

5.2.4刀齒幾何參數(shù)選擇..........................................................................................34

5.2.5確定齒升量....................................................................................................34

5.2.6確定齒距及同時工作齒數(shù)...............................................................................35

5.2.7確定容屑槽形狀和尺寸...................................................................................35

5.2.8設(shè)計分屑槽.............................................................................../....................36

5.2.9確定拉刀齒數(shù)和直徑......................................................................................37

5.3拉刀其他部分設(shè)計................................................................................................38

5.3.1拉刀柄部設(shè)計................................................................................................38

5.3.2頸部與過渡錐部設(shè)計......................................................................................38

5.3.3前導部、后導部設(shè)計......................................................................................39

5.3.4拉刀總長度....................................................................................................39

5.4拉刀強度及拉床拉力校驗......................................................................................40

5.4.1 拉削力..........................................................................................................40

5.4.2 拉刀強度校驗................................................................................................41

5.4.3 拉床拉力校驗................................................................................................41

5.5 本章總結(jié)..............................................................................................................42

6 結(jié)論..........................................................................................................................43

參考文獻......................................................................................................................44

致 謝............................................................................................................................45

... - 帮助:如何获取积分? 上传资料可以赚钱? 版权投诉

文檔留言 共有0條評論

熱門關(guān)鍵詞:

熱門關(guān)鍵詞:

豫公網(wǎng)安備 41072402000322號

豫公網(wǎng)安備 41072402000322號