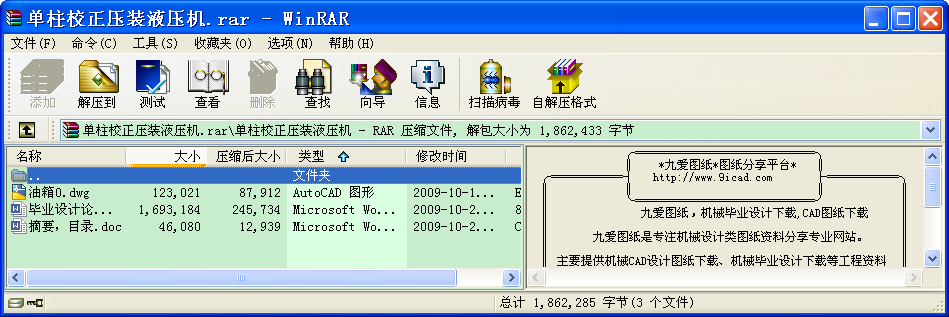

單柱校正壓裝液壓機

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 摘 要

Y41系列單柱校正壓裝液壓機,是一種多功能的中小型液壓機床,適用于軸類零件,型材的校正和軸套類零件的壓裝。它采用手腳聯動操作,通過電動機帶動液壓泵向主油路供油,通過溢流閥,手動換向閥等控制閥對液壓系統進行調壓換向,以達到各種工作狀態。

該液壓機結構緊湊,動作靈敏可靠,速度快,能耗小,噪音低,壓力和行程可在規定的范圍內任意調節,操作簡單。在本設計中,通過查閱大量文獻資料,設計了液壓缸的尺寸,擬訂了液壓原理圖。按壓力和流量的大小選擇了液壓泵,電動機,控制閥,過濾器等液壓元件和輔助元件。

關鍵詞:液壓機 液壓系統 調速回路;

目 錄

摘要··········································································Ⅰ

Abstract·····································································Ⅱ

第1章 緒論·································································1

1.1 課題背景·····························································1

1.2 發展趨勢·····························································1

第2章 方案論證···························································3

2.1 傳動方案的論證·····················································3

2.2 控制元件的分析·····················································4

第3章 液壓機的設計及參數選擇·········································5

第4章 工況分析···························································6

4.1 動力(負載)分析及負載循環圖··································6

4.1.1 摩擦負載······················································6

4.1.2 慣性負載······················································6

4.1.3 工作負載······················································7

4.1.4 負載循環圖···················································8

4.2 運動分析及運動循環圖·············································8

4.2.1 位移循環圖L—t·············································8

4.2.2 速度循環圖···················································9

第5章 確定液壓系統主要參數··········································10

5.1 確定液壓缸幾何尺寸··············································10

5.2 計算液壓缸所需流量··············································13

5.3 計算系統所需的壓力··············································13

5.4 繪制沖壓機主缸工況圖···········································15

5.5 液壓缸主要零件的結構材料及技術要求·························17

5.5.1 液壓缸的基本參數··········································17

5.5.2 液壓缸的類型和安裝方式··································18

5.5.3 液壓缸的主要零件及技術要求·····························18

5.6 液壓缸結構參數的計算···········································19

5.6.1 計算液壓缸的厚度··········································19

5.6.2 液壓缸油口的計算··········································21

5.6.3 缸底厚度的計算·············································21

5.7 液壓缸的校合······················································22

5.7.1 液壓缸中背壓力的校合·····································22

5.7.2 活塞桿的校合···············································23

第6章 擬訂液壓原理圖··················································24

第7章 液壓元件和液壓油的選擇········································26

7.1 液壓泵的選擇······················································26

7.1.1 確定泵的最大工作壓力·····································26

7.1.2 確定液壓泵的流量Q和排量q···························27

7.1.3 選擇液壓泵的規格··········································28

7.1.4 確定驅動液壓缸的功率·····································28

7.2 電動機的選擇······················································29

7.3 控制閥的選擇······················································29

7.4 管道(導管)的選擇·················································31

7.4.1 管道內徑的確定·············································31

7.4.2 管道壁厚b的計算···········································32

7.5 確定油箱的容量···················································33

7.5.1 液壓油的選擇···············································34

7.5.2 過濾器的選擇···············································34

7.6 聯軸器的設計·····················································34

第8章 液壓系統的性能驗算·············································36

8.1 管路系統壓力損失·················································36

8.1.1 沿程壓力損失的計算·······································37

8.1.2 管路內的局部壓力損失·····································38

8.1.3 閥類元件的局部壓力損失··································38

8.2 液壓沖擊的計算···················································39

8.3 液壓系統熱分析及其計算·········································41

8.3.1 液壓泵功率損失產生的熱流量(熱量)·····················41

8.3.2 液壓系統的散熱計算·······································42

第9章 限程裝置的設計··················································44

第10章 機架的設計······················································45

10.1 機架材料的選擇··················································46

10.2 肋的作用··························································46

第11章 液壓系統的安裝與調試·········································47

11.1 液壓系統的安裝··················································47

11.1.1 安裝前的準備工作·········································47

11.1.2 管子加工···················································47

11.2 液壓系統的調試··················································48

11.2.1 調試前的檢查··············································48

11.2.2 啟動液壓泵·················································48

11.2.3 系統排氣···················································49

11.2.4 系統耐壓實驗··············································49

12.2.5 負載試車···················································49

結論··········································································50

致謝··········································································51

參考文獻·····································································52 ...

文檔留言 共有條評論

熱門關鍵詞:

熱門關鍵詞:

豫公網安備 41072402000322號

豫公網安備 41072402000322號